Warehouse management software – which one to choose?

Warehouse management software – which one to choose?

What features should a good warehouse management software have?

Warehouse management software – which one to choose? Which system will work best for us?

WMS in practice

Warehouse management software - which one to choose?

If we are the owners of a company focusing on trade, servicing, production or leasing of warehouse space, it is in our interest to ensure the most effective management of the place where such activities take place. After all, the efficiency and productivity of our company depends on the efficiency and level of work organization. If we wanted to rely on our own strength and coordinate and monitor activities on our own, we would certainly not succeed. We would encounter failure in this matter especially when we were already running a large company. Then the scope of duties of our employees would be too large to cope with their implementation without taking shortcuts. So how can we improve our activities? Warehouse management software – which one to choose? Certainly one whose overriding advantage is the ability to achieve good results with low workload.

What features should a good warehouse management software have?

Warehouse management software – which one to choose? The features that such software should have are:

First of all, streamlining and automating the work of the staff. Thanks to this, it will minimize staff costs while operating effectively.

A proven partner with whom we will cooperate should offer software dedicated to our warehouse. In this way, we will ensure the effectiveness and efficiency of actions. We will also reduce the possible risk of errors and losses that could possibly occur. Based on modern software, we will improve the picking of goods and provide customer service at the highest level.

Good software should enable us to efficiently find specific goods by showing us where they are located. In addition, a modern system for managing our warehouse will not only allow us to indicate specific goods on the shelf, but also help us to pick up our products. As a result, the work will proceed at a much faster pace.

Another advantage that is important when choosing the software in question is the automation and improvement of the flow of information in the processes of storing and sending goods by specific entities. Nowadays, we can forget about the tedious, manual implementation of data or recording our clients on the so-called. on foot. Artificial intelligence can undoubtedly help us improve and reduce labor costs in our warehouse.

Warehouse management software - which one to choose? Which system will work best for us?

We mentioned in the previous paragraph how important it is to choose an experienced and reliable supplier of software that we would like to use. We also mentioned how important it is that this software is personalized and dedicated to our company.

In Poland, the most proven and recommended software dedicated to owners of logistics, service, commercial or production companies is WMS (Warehouse Management System). This system works online, using terminal connections and is directly coupled with the ERP system available in a given company. An important advantage of the discussed software is the fact that we can fully configure it. Thanks to this, we can meet our individual and current needs.

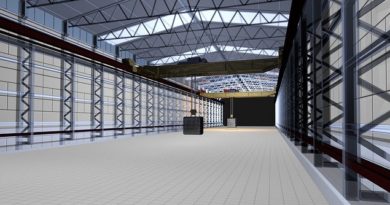

WMS software works best in high bay warehouses (3-5 levels). A warehouse worker in such warehouses is able to use a forklift to get to even the most inaccessible warehouse resources and storage areas. By implementing the WMS system, we increase the comfort of work, reduce its costs, and make our company more attractive in the eyes of potential contractors, and thus – more competitive. An important advantage of the implementation of the discussed software is the elimination of many mistakes made so far and the possibility of dealing with many formalities only electronically. Undoubtedly, it makes our work easier and shortens the time of many procedures that until now have been performed only on paper. Electronic invoices, records and lists of goods are just some of the advantages that we gain after implementing the program.

WMS in practice

In this paragraph, we will discuss the operation of the WMS software. Its functioning can be divided into the following elements:

- intra-warehouse logistics,

- release area,

- reception area.

The receiving zone applies to activities such as: acceptance of goods and their automatic identification, the so-called GS1 compliance. as well as quality and storage control. In the release zone, we monitor activities related to the preparation of products for shipment. We start them with making a list of products to be shipped. WMS allows you to accurately locate these products in the warehouse and determine their specification.

WMS also allows for quick actions in the following areas:

- taking into account all goods, including those from returns or other warehouses;

- quality control and verification regarding expiry dates (especially for food products);

- informing about the best possible location in the warehouse for most products and about possible surpluses, damage or shortages,

- generating ready-made labels necessary for shipments;

- intra-warehouse transfers and inventory activities.

The built-in tasks module ensures efficient management of warehouse activities by assigning tasks to individual employees. Thanks to this, you can honestly assess the employee’s performance, because this assessment is the result of reliable, documented information, and not subjective and biased opinions of the employer.